How are Kraft boxes made?

Are you curious about those sturdy brown boxes you see everywhere? Ever wonder how simple paper turns into a reliable Kraft box? Let's explore the journey from tree to box.

Kraft boxes primarily come from Kraft paper, produced via the Kraft pulping process which yields strong paper fibers. This paper is often used to create corrugated board, which is then cut, scored, folded, and glued or stitched into the final box shape.

That gives you the basic idea. But the world of box making has many layers, just like some types of cardboard! Stick with me, and we'll break down the manufacturing process for different boxes you likely encounter in your business.

How are cardboard boxes manufactured?

Running a business means dealing with packaging. Confused about how standard cardboard boxes are actually put together? Let's look at the main steps involved in making these essential items.

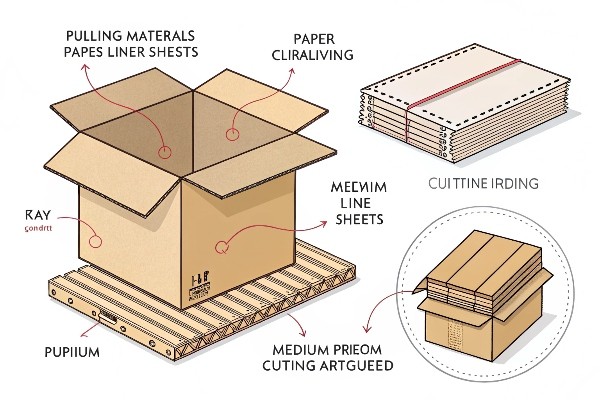

Cardboard boxes usually start with wood pulp or recycled fibers. These are made into paper sheets (linerboard and medium). The medium is corrugated, then glued between liner sheets. Finally, this board is cut, printed, folded, and secured.

!

Let's dive deeper into this manufacturing journey. It's a fascinating mix of raw material processing and precise machinery work.

From Raw Material to Board

It all begins with the source: wood chips from logs or recycled paper products. These materials go into massive pulpers. Here, they are mixed with water and chemicals (like in the Kraft process for virgin fibers) or mechanically processed to break them down into a slurry of fibers. This pulp is then cleaned and refined. Next, it heads to a papermaking machine, often a Fourdrinier machine. Water drains away, and the fibers mesh together, pressed and dried to form huge rolls of paper – either linerboard (the flat faces) or medium (the wavy inner layer).

Creating the Structure

The key to cardboard strength, especially for shipping, is corrugation. A corrugator machine takes the paper medium, heats it with steam, and passes it through large, toothed metal rollers (corrugating rolls) to create the familiar flutes or waves. Glue is applied to the tips of these flutes, and the linerboard sheets are pressed onto both sides. For stronger boxes (double or triple wall), more layers of medium and linerboard are added. This continuous sheet of corrugated board is then cut into large blanks, ready for the final steps. Quality checks happen frequently to ensure consistency.

| Feature | Single Wall Cardboard | Double Wall Cardboard |

|---|---|---|

| Layers | 1 Fluted, 2 Liners | 2 Fluted, 3 Liners |

| Strength | Standard | Higher |

| Common Use | Lighter items | Heavier items, Shipping |

What is the process of making a cardboard box?

Need the exact steps laid out clearly? Wondering about the sequence from start to finish? Let's trace the path a cardboard box takes during its creation, step by step.

The cardboard box making process includes: 1. Pulping raw materials. 2. Forming paper sheets (liner/medium). 3. Corrugating the medium layer. 4. Gluing liners and medium together. 5. Converting (cutting, printing, scoring). 6. Folding and gluing/stitching the box.

Understanding each stage helps appreciate the efficiency involved. I've seen these lines running in various factories during my travels, and it's quite something.

1. Pulp Preparation

As mentioned, this starts with wood or recycled paper. For Kraft paper, the chemical Kraft process is used, dissolving lignin to free up strong cellulose fibers. Recycled paper goes through de-inking and cleaning before pulping. The goal is a uniform fibrous slurry.

2. Papermaking

The pulp slurry is spread thinly onto screens on the papermaking machine. Water drains, suction pulls more water out, and then presses squeeze out even more. Finally, steam-heated rollers dry the paper completely, creating those giant rolls of linerboard or medium.

3. Corrugation and Assembly

The corrugator machine is the heart of the operation for corrugated boxes. It forms the flutes in the medium paper and uses adhesive (often starch-based) to bond the linerboard facings to the fluted medium, creating the rigid board structure.

4. Conversion (Finishing)

The large sheets of corrugated board now go to converting machines. A die-cutter cuts the board into the flat shape of the final box (the blank), including flaps and tabs. It also creates scores (creases) where the box will be folded. If printing is needed (like logos or handling instructions), it usually happens here, often using flexographic printing.

5. Folding and Joining

Finally, the flat, cut, scored (and possibly printed) blanks go to folder-gluers or stitchers. These machines automatically fold the blank along the score lines and apply adhesive (or sometimes stitches) to join the sides, forming the finished box, which is then bundled for shipping. Different box styles might require slightly different finishing steps 1.

How are shipping boxes made?

Do you rely heavily on shipping boxes? Concerned about whether they'll protect your goods in transit? Let's focus on how these workhorse containers are built for resilience.

Shipping boxes are primarily constructed from corrugated cardboard for its strength-to-weight ratio. Their manufacturing follows the standard process but emphasizes durability, often using stronger Kraft linerboard, specific flute types, or multiple walls for enhanced protection.

The magic of a shipping box lies in that corrugated structure. Let's look closer at why it works so well.

The Strength of the Flute

The wavy layer, the flute or medium, is the key. Those arches formed during corrugation create a structure that's remarkably strong and resistant to bending and pressure, much like arches in architecture. They also provide cushioning against impacts. The linerboard facings provide the flat surfaces and tensile strength.

Flute Types and Wall Construction

Not all corrugated board is the same. Different flute profiles offer different benefits:

- A-Flute: Largest flute, excellent cushioning, good stacking strength.

- C-Flute: Most common for shipping boxes, good all-around performance.

- B-Flute: Smaller flute, good crush resistance, good printing surface.

- E-Flute: Very small flute, often used for retail packaging needing finer print.

- F-Flute: Tiny flute, used for retail boxes, very smooth printing surface.

For heavy-duty shipping, multiple layers are combined: - Single Wall: One layer of fluting between two liners. Common for many shipments.

- Double Wall: Two layers of fluting separated by a central liner. Significantly stronger.

- Triple Wall: Three layers of fluting, extremely strong, used for very heavy or fragile industrial items.

Ensuring Performance

Manufacturers often test shipping boxes using standards like the Edge Crush Test (ECT), which measures stacking strength, or the Mullen Burst Test, measuring resistance to puncture. This ensures the boxes meet the demands of the shipping environment. Choosing the right construction is vital for product safety.

What is the difference between kraft and cardboard?

Hear these terms used often? Sometimes interchangeably? Let's clear up the difference between "Kraft" and "cardboard" so you know exactly what you're dealing with.

"Kraft" specifically means paper made using the strong Kraft chemical pulping process. "Cardboard" is a general term for heavy paper-based board, including paperboard (like cereal boxes) and, most commonly, corrugated fiberboard (which often uses Kraft paper liners).

Understanding this distinction is helpful when specifying packaging materials. Let me break it down further.Kraft Paper Explained

- Process: Made using the sulfate (Kraft) chemical process, which removes lignin effectively, leaving long, strong cellulose fibers.

- Properties: Known for high tensile strength, tear resistance, and durability. Usually brown, but can be bleached white. Often made from virgin wood fibers.

- Uses: Making high-strength paper bags, wrapping paper, and crucially, the linerboard layers in high-quality corrugated cardboard.

Cardboard as a Broad Category

"Cardboard" isn't a precise technical term in the industry but generally refers to:

- Paperboard (or Boxboard/Chipboard): A thick, single-ply paper material. Think cereal boxes, shoe boxes (the inner part sometimes), backing for notepads. It's less rigid than corrugated board.

- Corrugated Fiberboard: This is what most people mean by "cardboard" when talking about shipping boxes. It's the multi-layer material with fluting described earlier. High-quality corrugated board typically uses Kraft linerboard for its outer faces due to its strength.

| Feature | Kraft Paper | Cardboard (General Term) |

|---|---|---|

| Definition | Paper from Kraft pulp process | Heavy paper-based board |

| Structure | Single layer paper | Can be single-ply (paperboard) or multi-ply (corrugated) |

| Key Property | High Strength | Varies greatly (stiffness, thickness) |

| Relationship | Often a component of corrugated cardboard | Broad category, includes corrugated |

While Kraft-based corrugated boxes are fantastic for shipping and general use, sometimes you need a different kind of presentation, especially for high-value items like jewelry or electronics. That's where rigid boxes come in. These often use dense paperboard (chipboard) wrapped with specialty paper, requiring different machinery like forming machines 1 or corner pasting machines 2 for assembly. Techniques like grooving, instead of die-cutting, can create sharper, more premium-looking edges 345, which is something we specialize in at Kylin Machine for creating those high-end boxes people love 6. It's a different world from standard Kraft box production but shares the goal of protecting and presenting a product effectively.

Conclusion

So, Kraft boxes and cardboard boxes involve turning wood pulp or recycled fiber into paper, often creating corrugated structures, then cutting, folding, and joining them. Understanding this helps choose the right box.

-

Distributor Price list To arnold ↩

-

Detail of KY-1200A groove machine ↩

-

Detail of groove machine ↩

-

Detail of groove machine ↩

-

Office quote and answer to Jorge ↩

发表回复