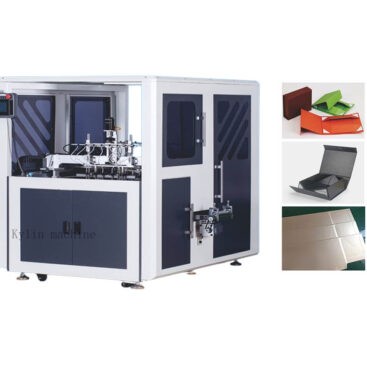

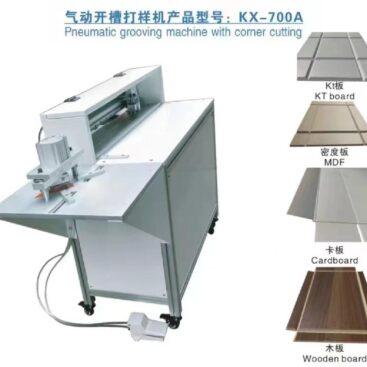

Specially designed for right-angle labels

Multi-functional right-angle labeling machine

-Available in various specifications, suitable for all kinds of carton boxes

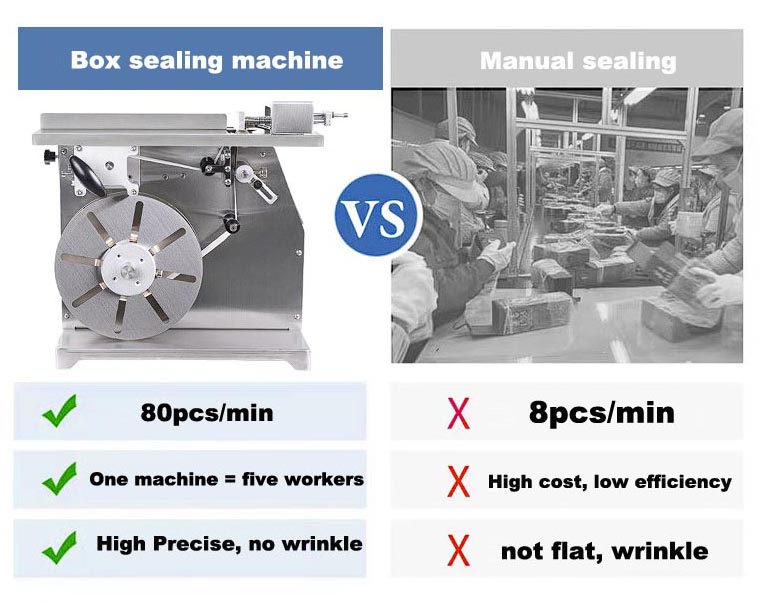

Still doing manual labeling??

Exquisitely crafted, excellent quality.

Wide range of applications

Widely used in all walks of life

Specially used for right - angle labeling, 90 - degree angle labeling, corner labeling. It can be used for corner labeling on the side of boxes to play a role in sealing and preventing unpacking. It is applied to anti - tampering labels on packaging boxes of cosmetics/electronic products/pharmaceuticals, etc., and is widely used in industries such as printing, food, daily chemicals, electronics, and pharmaceuticals.

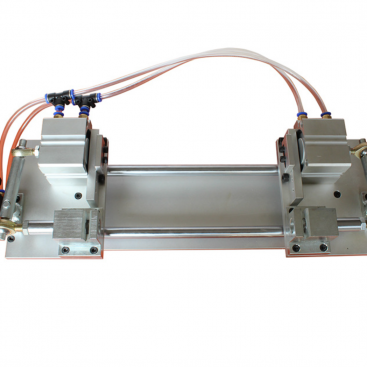

PLC Microcomputer Controller

Multifunctional PLC, flexibly set according to different needs. The program language can be switched between Chinese and English. It is controlled by high - quality chips, multiple data can be observed, the circuit board is stable and durable. One - key touch - screen operation makes your work more convenient.

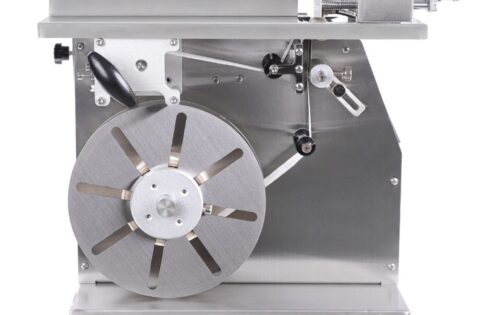

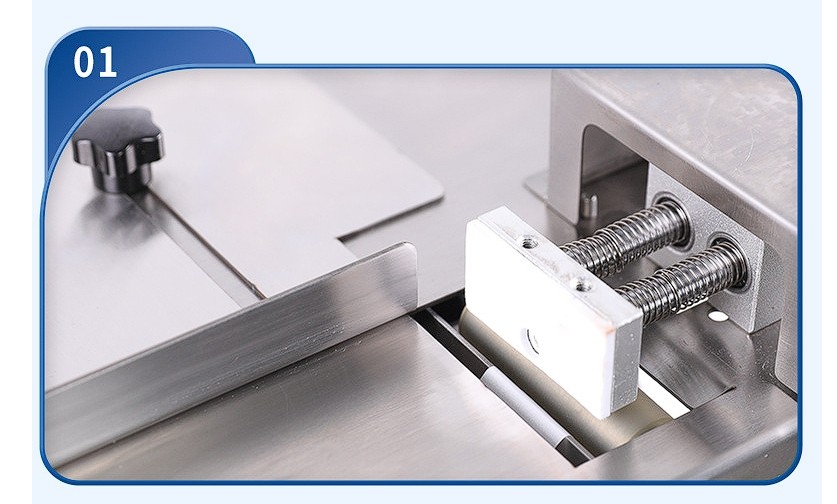

High - quality stainless - steel countertops.

The machine panel is wear - resistant and scratch - resistant, not easy to rust, and maintains a brand - new texture after long - term use.

The workbench surface can be adjusted according to the size of the packaging box and is suitable for round labels with a diameter of 15 - 50 MM (measured manually; for details, please consult the customer service).

The motor adopts a stepper motor

It can work continuously for 24 hours without burning out, and the output remains stable.

Machine specification

| Product Name | Box labelling/sealing machine |

|---|---|

| Labeling Speed | 35 - 90pcs/min (related to the proficiency of operation) |

| Power Supply | 220V 50HZ |

| Applicable Label Size | 15 - 50mm |

| Overall Machine Size | 35cm * 22cm * 32.4cm |

| Overall Machine Weight | 40kg |

| Applicable Label Roll | Outer Diameter 200mm, Inner Diameter 75mm |

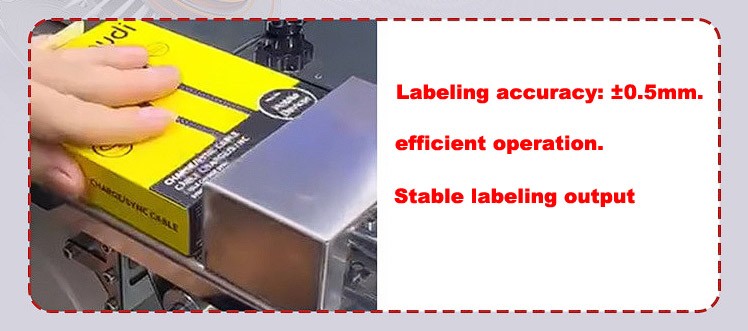

| Labeling Accuracy | ±0.5mm |

Machine details

Details are the best answer for everything

High - efficiency and precision, smooth labeling/applying labels.

Touch - screen control, capable of switching between Chinese and English, with intuitive, concise and easy - to - use operation.

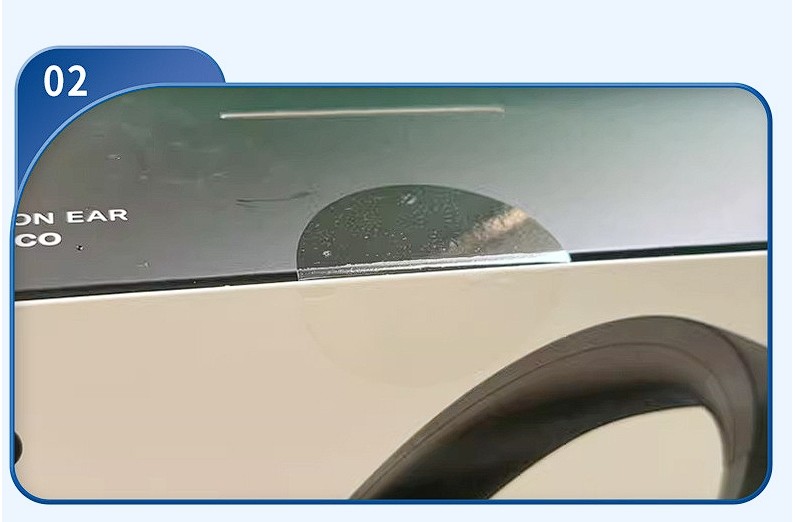

The labeling effect is beautiful, the cut is neat, and it is easy to tear open.

Stainless - steel body, more durable for use and easy to clean.

Side of the machine

Front of the machine

Customers said

Customers visitation

ADDITIONAL SERVICES

Customers Meeting&Machines Training

Meeting in India

Meeting in India

Meeting in Dubai

Meeting in Dubai

Trip to Turkey

Trip to Turkey

To help you master the installation and operation of your equipment, Kylin provides authorized training programmes led by surface preparation specialists.

- How to set up your machine and optimize performance levels for your process.

- Key trouble-shooting tips that keep your machine(s) in prime condition to minimize downtime, minimize maintenance, and prevent future problems.

- How to optimize performance levels to maintain consistent quality and minimize waste

- The latest legislation and how to keep the machine safe.

We offer three years machine quality warrantty, we want You to be satisfied with the work we do and our Machine,

Every time. We Guarantee to perform all good services to your complete satisfaction at the agreed upon price.

If at any time within 30 days after completion of the job you're not completely satisfied, we will Re-Clean all required areas to your satisfaction.

If you 're still not satisfied we will refund the money paid.

Help from technician is only a phone call away.

We offer free over the phone tech support to help you troubleshoot any issue you may be having.

If you require onsite help we are able to send our technicians to you! Whether it’s for training or support we can meet your needs.

Our experienced factory technicians are eager for you to get the most from your Kylin Machine.

We also offer to do regular maintenance to your machinery to make sure it stays in the best condition throughout the lifetime of the product.

This will help guarantee that your machines will work well for as long as possible.

Initially one of our experienced operators will try and help you resolve the problem over the telephone.

If that is not successful then we would send a field engineer out to site.

Our engineers carry the most common spare parts so that most problems can be repaired on site.

In the unlikely event that the machine could not be repaired on site, we would either arrange another on site visit if appropriate,

or take the machine in to our state of the art workshop where we can deal with all types of repairs and refurbishments

MEET OUR CUSTOMERS

We're not the only ones HappyExcited about KYLIN MACHINES

10,000 customers in 30 countries using KYLIN MACHINES, meet our customers