KY-425 Book Cover Corner Rounding Machine

Professional Grade Equipment for Precision Corner Rounding Operations

🎯 Achieve Perfect Corner Rounding with Professional Precision!

Get Your Quote Today!Professional Grade Corner Rounding Excellence

The KY-425 Book Cover Corner Rounding Machine represents the pinnacle of precision engineering for professional bookbinding and packaging operations. This robust machine delivers consistent, high-quality corner rounding with optimal processing dimensions and versatile material handling capabilities.

Engineered for high-efficiency production environments, the KY-425 features advanced corner radius options, stable construction, and compact footprint design. Perfect for commercial printing houses, bookbinding facilities, and packaging manufacturers requiring reliable corner rounding solutions.

Machine in Operation

Watch the KY-425 Book Cover Corner Rounding Machine demonstrate its precision and efficiency in professional production environments

Technical Specifications

Comprehensive technical specifications for the KY-425 Corner Rounding Machine

| Parameter | Specification | Details |

|---|---|---|

| Model | KY-425 | Professional grade |

| Working Size | 130 × 425mm | Optimal processing dimensions |

| Book Thickness | 1-4mm | Versatile material handling |

| Corner Radius | R10 (Standard) | Includes R10 mold set |

| Optional Radius | R6, R8, R12 | Additional mold options |

| Power Supply | 220V, 750W | Single-phase operation |

| Processing Speed | 15-25 books/hour | High-efficiency production |

| Machine Weight | 130kg | Stable, robust construction |

| Dimensions | 780×660×1350mm | Compact footprint |

| Packaging Size | 0.83×0.71×1.5M | Efficient shipping |

Ready to Enhance Your Production Quality?

Discover how the KY-425 can transform your corner rounding operations with professional precision

Request DemonstrationKey Features & Benefits

Advanced corner rounding technology designed for professional bookbinding and packaging operations

Precision Corner Rounding

Delivers consistent R10 standard radius with optional R6, R8, and R12 mold sets for versatile corner rounding applications across different material types and thicknesses

High-Efficiency Production

Processes 15-25 books per hour with reliable performance, ensuring optimal productivity for commercial bookbinding and packaging operations

Versatile Material Handling

Accommodates book thickness from 1-4mm with optimal working dimensions of 130×425mm, perfect for various book sizes and packaging materials

Robust Construction

130kg stable construction ensures consistent performance and durability, while maintaining a compact 780×660×1350mm footprint for efficient workspace utilization

Professional Grade Operation

Single-phase 220V, 750W power supply provides reliable operation with professional-grade performance standards for commercial environments

Efficient Installation

Compact packaging size of 0.83×0.71×1.5M ensures efficient shipping and easy installation in production facilities with minimal setup requirements

Applications & Industries

Professional corner rounding solutions for diverse bookbinding and packaging applications

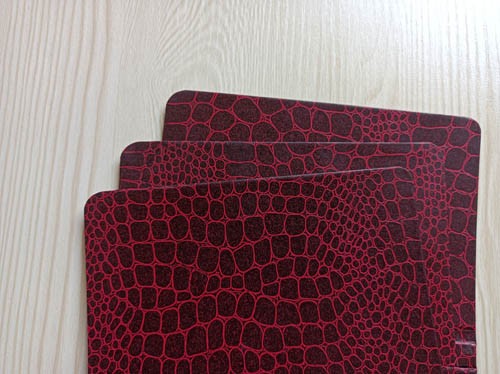

Professional Book Covers

Perfect corner rounding for hardcover books, journals, and premium publications requiring professional finishing with consistent radius precision

Commercial Bookbinding

Ideal for commercial printing houses and bookbinding facilities processing high volumes of books, catalogs, and bound materials with professional quality standards

Packaging & Presentation

Excellent for packaging materials, presentation folders, and premium packaging applications requiring precise corner finishing and professional appearance

Ready to Upgrade Your Corner Rounding Operations?

Contact us today for a demonstration and see how the KY-425 can enhance your production quality with professional precision

Get Quote NowCustomers said

Customers visitation

ADDITIONAL SERVICES

Customers Meeting&Machines Training

Meeting in India

Meeting in India

Meeting in Dubai

Meeting in Dubai

Trip to Turkey

Trip to Turkey

To help you master the installation and operation of your equipment, Kylin provides authorized training programmes led by surface preparation specialists.

- How to set up your machine and optimize performance levels for your process.

- Key trouble-shooting tips that keep your machine(s) in prime condition to minimize downtime, minimize maintenance, and prevent future problems.

- How to optimize performance levels to maintain consistent quality and minimize waste

- The latest legislation and how to keep the machine safe.

We offer three years machine quality warrantty, we want You to be satisfied with the work we do and our Machine,

Every time. We Guarantee to perform all good services to your complete satisfaction at the agreed upon price.

If at any time within 30 days after completion of the job you're not completely satisfied, we will Re-Clean all required areas to your satisfaction.

If you 're still not satisfied we will refund the money paid.

Help from technician is only a phone call away.

We offer free over the phone tech support to help you troubleshoot any issue you may be having.

If you require onsite help we are able to send our technicians to you! Whether it’s for training or support we can meet your needs.

Our experienced factory technicians are eager for you to get the most from your Kylin Machine.

We also offer to do regular maintenance to your machinery to make sure it stays in the best condition throughout the lifetime of the product.

This will help guarantee that your machines will work well for as long as possible.

Initially one of our experienced operators will try and help you resolve the problem over the telephone.

If that is not successful then we would send a field engineer out to site.

Our engineers carry the most common spare parts so that most problems can be repaired on site.

In the unlikely event that the machine could not be repaired on site, we would either arrange another on site visit if appropriate,

or take the machine in to our state of the art workshop where we can deal with all types of repairs and refurbishments

MEET OUR CUSTOMERS

We're not the only ones HappyExcited about KYLIN MACHINES

10,000 customers in 30 countries using KYLIN MACHINES, meet our customers