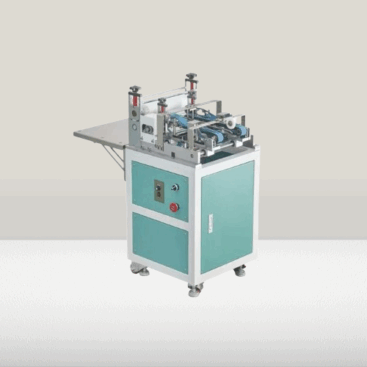

Carton Waste Stripper KY-680

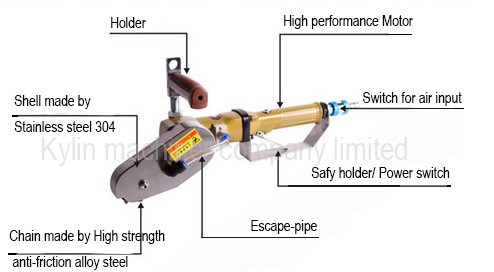

The Waste Stripper is equipped with a multi-tooth chain driven by a compressed air motor with an output of 400W. Its teeth do not catch the paper, they catch it. Your operator simply needs to hold the device, while the Waste Stripper takes care of the rest – a simple procedure, and incredibly quick. Overall, it strips up to 10 times quicker than by hand!

To simplify and reduce the operator's workload, the Waste Stripper can now be equipped with our load balancer, a support device which compensates for the weight of the Waste Stripper (4kg). The machine operator will then only have to guide the device, without supporting its weight.

Technical Specifications & Demo Video

Product Specifications

| Model | KY-680 |

| Weight of Paper | 150GSM-1000GSM cardboard, corrugated board |

| Grasping Frequency | 3000 R.P.M |

| Output Power | 800W |

| Air Consumption | 10 CFM |

| Noise (Next to Machine) | 91 dB |

| Noise (1m Away) | 86 dB |

| Ambient Noise | 34 dB |

| Net Weight | 4 Kg |

| Dimension | 470 × 170 × 220 mm |

Watch Demo Video

Product Application

Suitable Applications

The carton stripper, waste stripper is suitable for waste margin stripping of cardboard, thin corrugated paper and common corrugated paper in printing industry. Range for the paper is 150GSM-1000GSM cardboard, single and double corrugated paper, double laminated corrugated paper.

Spare Parts & Maintenance

Maintenance kit for the chain and spare chain available. The service life of the Waste Stripper chain depends on several factors: amount and length of use, type of materials stripped and maintenance. Daily lubrication significantly increases the chain's service life.

Key Features

High Strength Diamond Gear

For waste margin stripping of cardboard, thin corrugated paper and common corrugated paper. High speed running gear is cycle driven through air motor. The gear uses high strength diamond compound after heat treatment, high hardness, wear resistance, long life and easy replacement.

10x Efficiency Improvement

High efficient manual stripping equipment. Stripping efficiency is improved by 10 times. Manual stripping needs hours, finished only in 10-30 minutes with stripping machine, greatly shorten the delivery cycle.

Compact & Easy to Use

Compact configuration, almost the same weight as normal grinder, easy to use. Workers can operate the machine after simple training. No damage for bonding area while stripping, improve the efficiency of the following process (gluing/automatic packing).

German Pneumatic Motor

Uses original German Pneumatic motor for the power. Does not exist the problem that brush easy to be broken as ordinary hand-held grinder, and safety, long service life.

Ready to Boost Your Production Efficiency?

Get in touch with us today for pricing and more information

Customers said

Customers visitation

ADDITIONAL SERVICES

Customers Meeting&Machines Training

Meeting in India

Meeting in India

Meeting in Dubai

Meeting in Dubai

Trip to Turkey

Trip to Turkey

To help you master the installation and operation of your equipment, Kylin provides authorized training programmes led by surface preparation specialists.

- How to set up your machine and optimize performance levels for your process.

- Key trouble-shooting tips that keep your machine(s) in prime condition to minimize downtime, minimize maintenance, and prevent future problems.

- How to optimize performance levels to maintain consistent quality and minimize waste

- The latest legislation and how to keep the machine safe.

We offer three years machine quality warrantty, we want You to be satisfied with the work we do and our Machine,

Every time. We Guarantee to perform all good services to your complete satisfaction at the agreed upon price.

If at any time within 30 days after completion of the job you're not completely satisfied, we will Re-Clean all required areas to your satisfaction.

If you 're still not satisfied we will refund the money paid.

Help from technician is only a phone call away.

We offer free over the phone tech support to help you troubleshoot any issue you may be having.

If you require onsite help we are able to send our technicians to you! Whether it’s for training or support we can meet your needs.

Our experienced factory technicians are eager for you to get the most from your Kylin Machine.

We also offer to do regular maintenance to your machinery to make sure it stays in the best condition throughout the lifetime of the product.

This will help guarantee that your machines will work well for as long as possible.

Initially one of our experienced operators will try and help you resolve the problem over the telephone.

If that is not successful then we would send a field engineer out to site.

Our engineers carry the most common spare parts so that most problems can be repaired on site.

In the unlikely event that the machine could not be repaired on site, we would either arrange another on site visit if appropriate,

or take the machine in to our state of the art workshop where we can deal with all types of repairs and refurbishments

MEET OUR CUSTOMERS

We're not the only ones HappyExcited about KYLIN MACHINES

10,000 customers in 30 countries using KYLIN MACHINES, meet our customers