Can printed jewelry boxes be ordered in various sizes?

Struggling to find jewelry boxes that perfectly fit your unique pieces? Standard sizes often fall short, leaving items loose or crammed. Good news: getting custom sizes is absolutely possible.

Yes, printed jewelry boxes can definitely be ordered in various sizes. Custom sizing is standard practice, allowing boxes to be tailored precisely to fit specific jewelry items, thanks to modern, flexible manufacturing capabilities.

Getting the size right is crucial, but it's just one piece of the puzzle. Understanding how to determine the best size, measure accurately, and choose the right materials ensures your jewelry is presented beautifully and safely. Let's explore these details further.

What size should a jewelry box be?

Wondering about the ideal size for your jewelry box? Choosing the wrong size can make your precious items look lost or feel squished. The best size really depends on what you're packaging.

There isn't a single "correct" size for a jewelry box. The ideal dimensions depend on the type of jewelry (like a ring, necklace, or bracelet), how many pieces will be inside, and the overall presentation style you want.

!

Choosing the right size involves considering several factors. First, think about the item itself. A delicate ring needs a much smaller box than a chunky statement necklace or a watch. You also need to consider protection. The box should hold the item securely, often with an insert (like foam or velvet-covered card), to prevent it from moving around and getting damaged during handling or shipping.

Think about branding and perceived value too. A slightly larger box can sometimes feel more luxurious, but too large looks wasteful or careless. If you sell multiple items, consider if the boxes need to stack easily for storage or display.

Here’s a general guide, but remember customization is key:

| Jewelry Type | Typical Size Considerations | Example Internal Dimensions (L x W x H) |

|---|---|---|

| Rings | Small, snug fit, often with slot insert | 50 x 50 x 40 mm |

| Earrings (studs) | Small, similar to ring boxes, insert needed | 50 x 50 x 30 mm |

| Earrings (drop) | Slightly taller or longer box | 60 x 60 x 40 mm |

| Pendants/Charms | Small to medium, depends on chain length | 70 x 70 x 30 mm |

| Bracelets | Longer, flatter box, or deeper square box | 90 x 90 x 40 mm or 200 x 50 x 30 mm |

| Necklaces | Long, flat box to lay chain straight | 220 x 50 x 30 mm |

| Watches | Larger, deeper box with cushion insert | 100 x 100 x 70 mm |

The ability to produce this wide variety of sizes efficiently comes down to the manufacturing equipment. At Kylin Machine, our machines are designed for flexibility. For example, some of our equipment can handle box sizes ranging from a minimum of 40x40x10mm up to 400x400x100mm or even larger, depending on the model 12. This allows businesses using our technology to cater to diverse jewelry packaging needs.

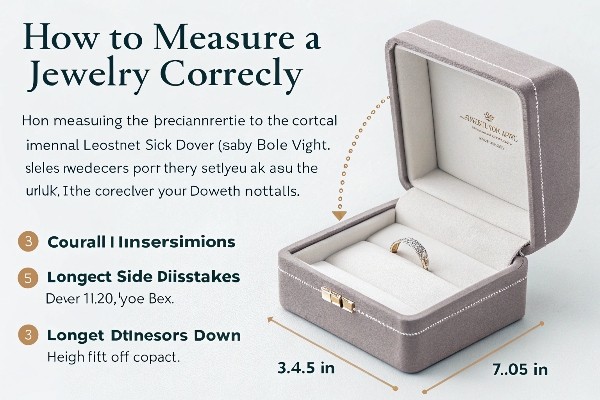

How do you measure a jewelry box?

Unsure how to specify the measurements for your custom jewelry boxes? Getting the dimensions wrong can lead to costly mistakes and delays. Thankfully, it's straightforward: measure Length x Width x Height.

To measure a jewelry box correctly, focus on the internal dimensions: Length (the longest side when looking down), Width (the shorter side), and Height (the depth or thickness). These inside measurements ensure your jewelry actually fits.

It’s important to distinguish between internal and external dimensions.

- Internal Dimensions (L x W x H): These are the most critical measurements. They define the usable space inside the box. Measure the length, width, and height of the cavity where the jewelry will sit. Always measure the jewelry piece first, then add a little extra space (clearance) for ease of placement and removal, and to accommodate any insert. A few millimeters extra on each side is usually sufficient.

- External Dimensions: These measure the outside of the box. They are important for designing shipping cartons, planning storage space, and calculating display area requirements. The external size will always be slightly larger than the internal size due to the thickness of the box walls (usually made from greyboard or chipboard).

Measurement Guide:

| Dimension | How to Measure | Why it Matters |

|---|---|---|

| Internal L | Longest side of the inside space | Ensures item fits lengthwise |

| Internal W | Shorter side of the inside space | Ensures item fits widthwise |

| Internal H | Depth from bottom to top edge inside | Ensures item fits without being crushed by lid |

| External LWH | Measure the full outside of the closed box | Needed for shipping, storage, outer packaging design |

Always specify the units you are using, typically millimeters (mm) for precision in box manufacturing, or sometimes inches (in). Consistency is key. Providing accurate internal dimensions is vital when ordering custom boxes. Manufacturing processes, especially automated ones like those using Kylin machinery, rely on these precise inputs to create boxes that meet specifications perfectly 123. Our machines are built to work accurately within their specified size ranges, ensuring the final product matches the required dimensions.

What packaging is best for jewelry?

With so many packaging options available, how do you choose the best one for jewelry? Making the wrong choice could risk damage to the items or fail to convey the quality of your brand. Rigid boxes often strike the perfect balance.

Rigid boxes, often called gift boxes or setup boxes, are frequently the best packaging choice for jewelry. They offer excellent protection, a premium look and feel, and provide a great surface for high-quality printing and branding finishes.

Rigid boxes stand out for several reasons. Their construction, typically using thick chipboard (greyboard) wrapped in paper or other materials, provides superior strength and durability compared to folding cartons. This protects delicate jewelry from bumps and pressure. The sturdy nature also conveys a sense of luxury and value, enhancing the customer's unboxing experience.

Furthermore, the flat surfaces of rigid boxes are ideal for various printing techniques, embossing, debossing, foil stamping, and special finishes, allowing for strong brand expression. They often come with custom-fitted inserts (foam, velvet flock, etc.) to hold jewelry securely.

While rigid boxes are excellent, other options exist:

- Pouches (Fabric/Velvet): Soft, good for scratch protection, lower cost. Less protection against impact, less branding space.

- Folding Cartons: Lower cost than rigid boxes, ship flat. Offer less protection and perceived value.

- Plastic Boxes: Durable, transparent options available. Can sometimes feel less luxurious unless well-designed.

Here’s a quick comparison:

| Packaging Type | Protection Level | Perceived Value | Customization | Typical Cost |

|---|---|---|---|---|

| Rigid Box | High | High | Excellent | Medium-High |

| Fabric Pouch | Low (impact) | Medium | Good (print) | Low |

| Folding Carton | Medium-Low | Low-Medium | Good | Low-Medium |

| Plastic Box | Medium-High | Variable | Fair | Low-High |

For businesses aiming for a high-quality presentation that protects the product well, rigid boxes are usually the preferred solution. This is precisely the type of packaging that Kylin Machine specializes in producing. Our range of equipment, including forming machines and case makers, is designed to efficiently manufacture high-quality rigid boxes suitable for jewelry and other luxury items 413.

What is the best material for the inside of a jewelry box?

Worried that the inside of your jewelry box might scratch or tarnish the precious items within? The lining material matters greatly for both protection and presentation. Soft, non-abrasive materials are essential.

Soft fabrics like velvet, velveteen, suede (or faux suede/suedette), and satin are generally the best materials for lining the inside of a jewelry box. They are non-abrasive, help prevent scratches, can reduce tarnishing, and provide a luxurious feel.

The primary purpose of the lining is to protect the jewelry. Metals can scratch, gemstones can chip, and materials like silver can tarnish when exposed to certain chemicals or air. A good lining minimizes these risks.

Here are some popular choices for inserts and linings:

- Velvet/Velveteen: Classic choice, very soft, luxurious appearance. Available in many colors. Good cushioning.

- Suede/Faux Suede (Suedette): Offers a soft, matte finish. Also feels luxurious and provides good protection.

- Satin: Smooth, shiny finish. Looks elegant but might be slightly less cushiony than velvet or suede.

- Flocked Foam/Card: Foam or card base coated with short fibers (flocking) to mimic velvet. Often used for inserts with cutouts to hold items securely. Provides structure and softness.

- Foam (Plain): Often used for inserts (like EVA foam). Provides excellent cushioning and can be precisely cut, but may not look as luxurious unless covered.

Lining Material Comparison:

| Material | Softness | Scratch Protection | Luxury Feel | Tarnish Resistance* | Typical Use |

|---|---|---|---|---|---|

| Velvet/Velveteen | High | Excellent | High | Good | Full lining, pads |

| Suede/Suedette | High | Excellent | High | Good | Full lining, pads |

| Satin | Medium | Good | Medium-High | Fair | Lining, pillows |

| Flocked Insert | Medium | Good | Medium | Good | Shaped inserts |

| Foam (EVA) | Low | Fair (edges) | Low | Poor | Shaped inserts |

*Tarnish resistance depends partly on chemical treatments; sulfur-free materials are best.

When choosing, consider the type of jewelry, your brand aesthetic, and budget. Darker linings often create a dramatic contrast with metals and gems, while lighter colors can feel fresh and modern. While Kylin Machine focuses on manufacturing the box structure itself, understanding lining materials helps our clients design the complete, perfect package for their jewelry products. The quality of the box structure made by our machines provides a solid foundation for these beautiful and protective interiors.

Conclusion

Yes, you can absolutely order printed jewelry boxes in custom sizes. Determine the size based on the item, measure carefully (LWH inside), choose rigid boxes for quality protection and branding, and select soft inner linings like velvet or suede.

At Kylin Machine (www.kylinmachines.com), we provide the advanced machinery that enables businesses worldwide to produce these high-quality, customizable rigid boxes efficiently.

-

of this Machine can be Customized Gift boxes, rigid boxes,Decoratiove boxes, inner box, or outside box Minimum finished Case size: 40X40X10(mm) Capacity: 1pcs/sec Power:0.5HP/200V Overall Dimension(LWH): 800X500X1400(mm) Packaging Dimension(LWH): 850X550X1500(mm) Machine Weight: 200Kg Packaging Volume: 1CBM Power Supply 380V/50HZ Max pressing size 750*650mm Max height 20-500mm Max pressure 5T power 2.2kw Machine Dimensions(L× W× H) 1150× 960× 920mm Machine Weight 200kg ↩ ↩ ↩

-

required a box box press and fold machine with 8 air cylinders. It can make 4-8sides of boxes. The cost is a little higher, which is US$19,800 Please share Max and min dimensions and a video of this model You can download video from link: https://we.tl/t-zRNLrlQpx8 Specification Max size: 400X400X100mm Min size: 70X70X15mm ↩ ↩

-

Machine US$8,500 Picture Picture Specifications Description US$2,500 KY-550C Box Forming Machine KY-40 Box Corner Pasting Machine Box forming machine is used to glue the cover paper on the four sides of box, Make the cover paper coat and fold-in one after another Gift boxes, Rigid boxes,Decoratiove boxes, Shoe Box, Phone Box, and other deluxe packaging boxes US$5,800 Finished Case Size(minimum): 100X80X15(mm) Finished Case Size(Maximum): 360X500X100(mm) Capacity:20-40pcs/min Power:1HP/380V Overall Dimension(LWH): 1450X1100X2650(mm) Packaging Dimension(LWH): 1500X1170X2040(mm) Machine Weight: 600Kg Packaging Volume: 4CBM Gift boxes, rigid boxes,Decoratiove boxes, inner box, or outside box ↩ ↩

-

of boxes. 3. Environmental hot-melt adhesive tape is used to paste corner 4, The length of tape can be adjustable from 5mm to 35mm 5, Size of this Machine can be Customized Application: Gift boxes, rigid boxes,Decoratiove boxes, inner box, or outside box Dealer Price: 1900 --- Picture: KY-180 Paper boxes press machine --- Specifications: |- Finished Case Size(minimum): 100X80X15(mm) Finished Case Size(Maximum): 360X500X100(mm) Capacity:20-40pcs/min Power:1HP/380V Description: >- Paper boxes pressing machines is used to avoid and press the bubble on the surface of the paper boxes, it is wild used in the packaing industry. Application: Gift boxes, rigid boxes,Decoratiove boxes, inner box, or outside box Dealer Price: 900 === === ↩

发表回复