How Are Rigid Boxes Made?

Rigid Boxes (also called “Set-Up Boxes”) are a very common type of packaging and they are often associated with luxury products. Rigid boxes are typically four times thicker than an average folding carton and are not usually printed on directly. They are instead wrapped with paper that can be as plain or luxurious as desired.

(If you are need a quick explanation on the 3 different types of boxes in the packaging world, click here.) (Also, check out a more comprehensive gallery of rigid box styles – here)

Rigid boxes, as the name suggests, are rigid and sturdy. Think of the classic “Shoe Box”. If you’ve ever purchased a nice pair of shoes or heels, they will have been packaged in a rigid box. Board games are another classic example of rigid box packaging. iPhones and other high-end electronics use rigid boxes, as do many beauty and high-end food products and spirits, just to name a few.

How Are Rigid Boxes Made?

Most of the processes are either done by rigid box machine or hand or various combinations of the two, depending on the specific manufacturer.

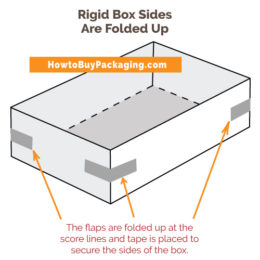

Rigid boxes start out as sheets of what is called chipboard (or greyboard or plainboard) which is like the color of newspaper (there is also an option for colored chipboard that will give color to the inside of the box). Cutting and scoring dies are used to cut the chipboard to its correct shape and size, while the sides of the box are scored (not cut all the way through to facilitate folding).

The box sides are folded up at the score areas to complete the box form. Tape is then applied to secure or “stay” the sides using a machine called a quad stayer.

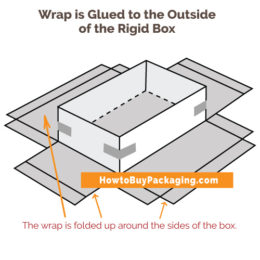

The wrap is prepared by having it printed-on (if desired) then trimmed or “mitred” to perfectly fit the box. The box is then placed on the wrap where glue is used to adhere the two together.

Wraps can be all types of paper or fabrics with a staggering array of textures and colors and finishes (i.e. high gloss or matte) including embossing, foil stamping and flocking (adding sparkles). For a look at different kinds of custom box embellishments.

By using the box wrapping machine, the wraps can also be either tightly or loosely wrapped around the box. Traditionally, when rigid boxes were all hand-made, the wraps were always loosely wrapped. Now the norm is to wrap the box tightly. People can still usually opt to have their rigid boxes with loose wrap; it gives the box an air of being hand-made and therefore more expensive and luxurious.

copied via how to buy packaging

发表回复