How many types of retail boxes are in the packaging world?

Confused by the endless styles of retail boxes you see? Choosing incorrectly can hurt your brand's image and sales. Let's explore the main types to help you choose wisely.

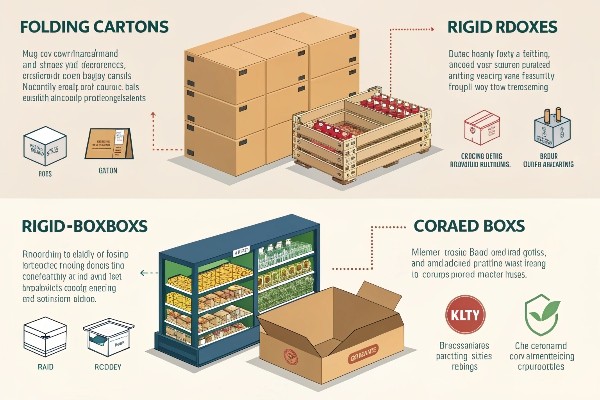

There isn't one simple number for retail box types. They vary hugely based on material, structure, and purpose. Key categories include folding cartons, rigid boxes, and corrugated boxes, each with many styles.

Understanding the different kinds of boxes available is the first step. But knowing why they differ helps even more when you need to package your product effectively. We need to look closer at the categories and definitions to see how they apply to your business, especially if you're involved in making these boxes. Let's break down some common questions people ask about packaging boxes.

How many types of packaging boxes are there?

Feeling overwhelmed by all the box choices? This confusion makes selecting the right production method difficult. Let's simplify the main types relevant to your packaging business needs.

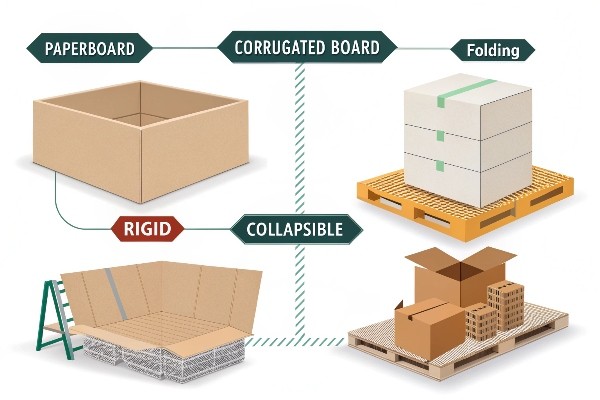

Packaging boxes fall into several broad categories based on material (like paperboard, corrugated board) and structure (like folding, rigid, collapsible). Each type offers different levels of protection and presentation.

When we talk about packaging boxes, we're covering a lot of ground. From the simple carton holding cereal to the fancy box for a new phone. In my line of work at Kylin Machine, helping businesses produce these boxes, I see how important it is to match the box type to the product and the brand.

Material Matters

The material is often the first way we sort boxes:

- Paperboard/Cardstock: Thin but sturdy. Used for folding cartons like food packaging or cosmetic boxes. Easy to print on.

- Corrugated Cardboard: Has fluted layers between liners. Stronger, used for shipping but also for retail displays or heavier items. Comes in different strengths (flute sizes).

- Rigid Board (Greyboard/Chipboard): Thick, dense paperboard. Doesn't fold flat easily. Used for high-end rigid boxes, offering excellent protection and a premium feel. This is a key area for my company's machines.

- Plastic: Sometimes used for clear retail boxes or durable containers.

Structural Styles

How a box is built is just as important:

- Folding Cartons: Made from die-cut paperboard, shipped flat, and assembled when needed. Very common for retail shelves.

- Rigid Boxes (Set-up Boxes): Made from thick board, arrive pre-assembled. Think luxury goods, electronics. Our Robotic Spotters and Hybrid machines excel at producing these efficiently.

- Corrugated Boxes: Strong, often used for shipping or bulk retail (like Costco). Can also be printed for branding.

- Specialty Boxes: Includes styles like collapsible rigid boxes (saving space but offering luxury), round boxes, or custom shapes. We also offer machines for these specific types.

Understanding these basic types helps businesses decide not just on packaging, but also on the machinery needed to produce them effectively.

| Box Type | Common Material | Key Feature | Typical Use | Kylin Machine Focus? |

|---|---|---|---|---|

| Folding Carton | Paperboard | Ships flat, foldable | Cereal, cosmetics, meds | Indirectly |

| Rigid Box | Rigid Board | Sturdy, premium feel | Phones, jewelry, gifts | Yes (Core) |

| Corrugated Box | Corrugated Cardboard | Strong, protective | Shipping, bulk retail | No |

| Collapsible Box | Rigid Board | Premium, saves space | Luxury goods, flat-pack | Yes |

| Round Box | Rigid Board/Paper | Unique shape | Hats, gifts, specialty food | Yes |

What is a retail packaging box?

Does 'retail packaging' just mean any box a product comes in? Using the wrong kind of box on the shelf costs you customer interest. Let's clarify what makes packaging truly 'retail'.

A retail packaging box is designed specifically for selling products directly to end consumers. Its main job is to attract attention, protect the item, provide information, and represent the brand effectively.

Think about when you walk down a store aisle. The boxes you see are all competing for your attention. That's the essence of retail packaging. It's not just a container; it's a marketing tool. It’s very different from a plain brown shipping box that only focuses on protection during transit. In my experience helping clients produce packaging, the focus is always on how the box performs at the point of sale.

Branding & Shelf Appeal

This is maybe the most crucial part. A retail box needs to look good and instantly communicate the brand's identity.

- Visuals: Uses colors, graphics, logos, and finishes (like gloss or matte) to stand out.

- Shape & Structure: Unique shapes or opening styles can grab attention. Think about premium rigid boxes – their solid feel implies quality. Making these consistent requires precise machinery.

Product Protection

While looks matter, the box must still protect the product.

- Integrity: Needs to withstand shelf stocking and customer handling.

- Inserts: Often includes internal structures (made of paperboard or other materials) to hold the product securely.

Consumer Information

The box tells the customer what they need to know.

- Product Details: What the product is, its features, size, ingredients.

- Usage Instructions: How to use the product.

- Brand Story: Sometimes includes a bit about the company or its values.

Creating a box that balances all these needs – looking great, protecting the contents, and informing the customer – is key. For brands using higher-end packaging like rigid boxes, the quality of the box itself, made possible by machines like our Kylin Robotic Spotters, becomes part of the brand message.

How many types of packaging do we have?

Thinking packaging is only about boxes? This narrow view might limit your options and miss opportunities. Let's explore the broader world of packaging types relevant for retail products.

Packaging is typically categorized into primary, secondary, and tertiary types. Retail boxes usually fall under secondary packaging, which groups products or adds branding for the shelf.

It's useful to think about packaging in layers. Each layer has a different job. Understanding this helps you see where retail boxes fit in the bigger picture.

- Primary Packaging: This is the layer that directly touches the product. Think of the bottle holding soda, the wrapper on a candy bar, or the blister pack holding pills. Its main job is containment and protection of the product itself.

- Secondary Packaging: This layer groups primary packages or adds another layer of branding and protection for retail display. This is where most retail boxes fit in – like the box holding multiple candy bars, the carton around a toothpaste tube, or the rigid box for a smartphone. Its job includes branding, display, and sometimes grouping units.

- Tertiary Packaging: This is used for bulk handling, storage, and shipping. Think of large corrugated boxes holding many retail units, or shrink wrap around a pallet. Its focus is purely on logistics and protection during transit.

Our focus at Kylin Machine is mainly on producing machinery for high-quality secondary packaging, especially the types that make a big impact on the shelf.

Focusing on Secondary Retail Boxes

Within secondary packaging, we find the retail box types we discussed earlier:

- Folding Cartons: Widely used across many industries.

- Rigid Boxes (Set-up Boxes): These offer a premium experience. They come in styles like two-piece (lid and base), hinged lid, or drawer style. Producing these with precision is where our advanced machines like the Robotic Spotter and Hybrid systems shine. They ensure perfect alignment and assembly for that luxury feel.

- Corrugated Boxes: Sometimes used as retail-ready packaging (RRP) that goes directly onto shelves.

- Collapsible Rigid Boxes: A smart option combining the luxury feel of rigid boxes with the space-saving benefits of folding cartons during shipping. Our specialized machines cater to this growing market too.

- Round Boxes: Offer a distinct look for specific products. We provide machinery for creating these cylindrical containers as well.

So, while packaging is broad, the retail box as secondary packaging is a critical area, particularly for making a product stand out. My work involves helping businesses create these impactful boxes efficiently and consistently.

What is a retail box?

Is any box found on a store shelf technically a 'retail box'? Misunderstanding its specific role can lead to ineffective packaging design. Let's define its core purpose clearly.

A retail box is the consumer-facing container holding a product intended for sale. Its main jobs are to capture buyer attention, safeguard the contents, and clearly communicate brand value at the point of purchase.

This might sound similar to the definition of retail packaging, but here we emphasize the box itself as the primary interface between the product and the customer in the store. It’s the silent salesperson on the shelf. When I talk with clients in the printing and packaging industry, we often discuss how the physical box needs to perform several key functions simultaneously.

Attracting Attention

In a crowded retail space, the box must stand out.

- Graphics and Color: Bold designs, appealing color palettes.

- Shape and Uniqueness: Non-standard shapes or interesting textures can draw the eye.

- Finishes: Embossing, foil stamping, or special coatings add perceived value.

Protecting the Product

The box ensures the product reaches the customer in perfect condition.

- Structural Strength: Must withstand handling without crushing or damage.

- Secure Closure: Prevents tampering or accidental opening.

- Internal Fitments: Inserts might be needed to hold items securely.

Communicating Information

The box provides necessary details quickly.

- Brand Identity: Logo and brand name prominently displayed.

- Product Features: Key benefits and selling points are highlighted.

- Instructions & Legal Info: Usage guides, ingredients, warnings.

Facilitating Purchase

The box should make buying easy.

- Easy to Handle: Customers should be able to pick it up easily.

- Stackable/Displayable: Designed for efficient stocking on shelves.

- Clear Value Proposition: The overall presentation should justify the price.

Comparing common retail box types highlights these functions:

| Feature | Folding Carton | Rigid Box |

|---|---|---|

| Visual Appeal | Good; high print quality possible | Excellent; premium feel, allows complex finishes |

| Protection | Moderate | Excellent; very strong structure |

| Perceived Value | Standard to Good | High to Luxury |

| Cost | Lower | Higher |

| Best For | Everyday items, mass market goods | Premium goods, gifts, electronics |

The quality of manufacturing is critical here. A poorly made box, even with a great design, undermines the brand. That's why precision machinery, like the Kylin machines my company builds for creating flawless rigid boxes, is so important for businesses serving brands that rely on packaging to convey quality. Consistent, high-quality production is key.

Conclusion

Many retail box types exist, serving different needs. Understanding them helps you choose the best packaging and, importantly, the right production methods – like Kylin machines for premium boxes – for success.

About me:

My Name: Jacob

Link to my website: www.kylinmachines.com

Brand Name: Kylin Machine

Country: China

Products: Post-press machines (Specializing in Robotic Spotter and Hybrid systems for rigid box and hard book cover solutions)

Business Model: B2B, Wholesale only

Kylin Machine helps packaging and printing businesses worldwide produce high-quality rigid boxes, collapsible boxes, round boxes, and hardcovers efficiently.

发表回复