How to make awesome custom packaging boxes?

Want your products to fly off shelves? Basic boxes blend in easily. Stand out from the crowd with packaging that truly wows your customers and makes them remember you.

Awesome custom boxes blend smart design, quality materials, and precise manufacturing. Focus on your brand identity, product protection needs, and the unboxing experience to create packaging that impresses buyers effectively.

That sounds simple enough on the surface. But how do you actually do it step by step? Let's break down the process to create packaging that gets noticed by everyone and really reflects your brand's quality. Making great packaging is key to making a great first impression.

How to make a unique packaging?

Tired of using generic, boring packaging? Uniqueness makes your brand memorable and stand out. Ordinary boxes just don't cut it anymore in today's crowded market.

Make your packaging unique through distinct shapes, special textures, and premium finishes. Choose special papers12, add custom inserts, or use eye-catching print techniques like foil stamping2 to create a memorable first impression.

!

Creating unique packaging goes beyond just a different color. It involves several elements working together. Think about the materials first. You can choose standard cardboard, but exploring options like textured paper, recycled content, or specialty papers with unique feels can make a big difference12. The structure is also vital. Instead of a standard rectangular box, consider different shapes, maybe cylinders, or boxes with special closures like ribbons or magnets2. We've even seen machines designed to handle various box shapes, although they might cost a bit more3. Then there are the finishes. Simple printing is standard, but techniques like embossing (raised designs), debossing (indented designs), foil stamping (shiny metallic print)2, or spot UV (shiny coating on specific areas) add a touch of luxury and visual interest. Combining these elements thoughtfully results in packaging that tells your brand's story.

Material Magic

Choosing the right paper or board sets the stage. Think about weight, texture, and color. Coated papers offer vibrant printing, while uncoated or Kraft papers give a more natural feel12.

Structural Standouts

The shape and opening mechanism contribute hugely to uniqueness. Consider drawer-style boxes, hinged lids, or magnetic closures2 for a premium feel. Even the way a box opens can be part of the brand experience.

Finishing Flourishes

These are the final touches that elevate the design. Hot stamping a logo2, adding a soft-touch laminate, or using UV printing2 for vibrant graphics can make packaging feel special and high-end.

How can I design my own packaging?

Have a great vision for your brand? Translating that vision effectively onto your packaging can sometimes be tricky. Don't let poor packaging design undermine your product's appeal or quality.

Design your own packaging by first defining your brand identity clearly and understanding your target customer. Consider product protection needs and the desired unboxing feel. Use design software or work with a professional packaging designer.

Designing your own packaging starts with a solid plan. First, really understand your needs. Who is your customer? What message does your brand convey (luxury, eco-friendly, playful)? How fragile is your product? What kind of unboxing experience do you want to create? Answer these questions first. Then, start sketching ideas or creating mood boards. Look at competitor packaging and see what you like or dislike. Once you have a concept, you need to think technically. This involves creating a dieline (the flat template for the box) and specifying materials12 and print finishes2. Software like Adobe Illustrator or specialized CAD programs are often used. It's also smart to consider manufacturing early on. We at Kylin Machinery often see great designs that need slight adjustments to be produced efficiently on automated machines, like our rigid box makers4. Getting a physical prototype made is a crucial final step before committing to a large production run.

Know Your Goals

Define your brand, audience, budget, and protection requirements. This foundation guides all design choices.

Sketch and Refine

Translate ideas into visual concepts. Use sketches, digital mockups, or mood boards. Get feedback and iterate on the design.

Technical Details Matter

Create accurate dielines. Specify colors (like Pantone colors2), materials12, and finishes2. Ensure your design files are print-ready. Consider how machines will assemble the box54.

How to make your own packaging box from scratch?

Want full control over the box-making process? Building packaging entirely from scratch seems like a big task. It involves many detailed steps beyond just folding some cardboard.

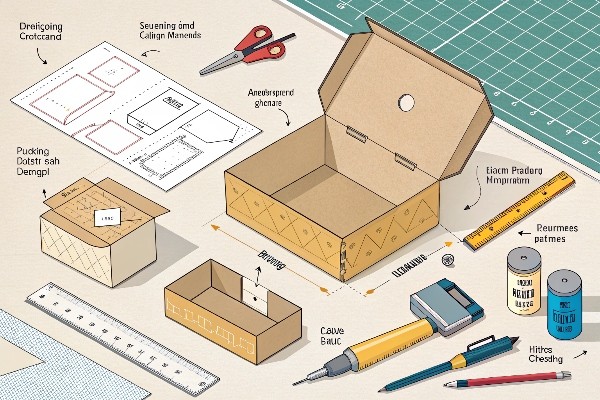

Making boxes from scratch involves designing, sourcing materials like board and paper12, precise cutting and scoring, printing graphics if needed, and finally assembling using folding and gluing techniques, often with specialized machinery564.

Making a box from scratch, especially a high-quality one, involves several production stages. It starts with getting the right raw materials – usually sturdy greyboard for the core and chosen paper for the wrap12. Then comes shaping the materials. This often involves die-cutting machines (like '啤机' mentioned in reference 2) to cut the flat shapes and scoring or V-grooving machines ('V槽机'2) to create sharp, clean folds for rigid boxes. If graphics are involved, printing happens on the paper wrap before assembly2. The assembly is where it all comes together. For rigid boxes, this typically involves gluing the wrap, applying it to the board, folding the edges, and often using corner taping machines for reinforcement6. Finally, the box might be pressed to ensure strong adhesion and remove air bubbles6. For quality and efficiency, especially for complex or high-volume rigid boxes like those used for jewelry, gifts, or electronics4, specialized machinery is essential. Our Kylin machines, for example, automate steps like gluing, forming54, and corner pasting6, ensuring consistent results and faster production speeds.

Gathering Supplies

Source appropriate cardboard or paperboard12 and any special cover papers or liners2. Don't forget adhesives like jelly glue1 or hot melt tape6.

Shaping the Box

Use precise cutting methods like die-cutting2. For rigid boxes, V-grooving2 creates sharp 90-degree corners.

Bringing it Together

This involves applying glue, wrapping the paper over the board, folding sides, and securing corners564. Machines ensure accuracy and speed here564.

What is the cheapest product packaging?

Need packaging options but working on a very tight budget? Expensive, elaborate boxes aren't always feasible or necessary. But be careful, the absolute cheapest option might hurt your brand image.

The cheapest packaging is usually simple folding cartons made from thin cardstock, basic Kraft mailers, or plain poly bags. Minimal printing and standard shapes help keep costs down significantly.

Finding the absolute cheapest packaging means simplifying things. Thin, standard folding carton boxes made from chipboard or Kraft paper are often the lowest cost for box structures. Poly mailers are very cheap for soft goods. Minimal printing, perhaps just one color, costs less than multi-color or photo-quality printing2. Avoiding special finishes like lamination, foil stamping, or embossing2 also saves money. Standard shapes and sizes are cheaper to produce than custom designs. Buying in very large volumes can reduce the per-unit cost significantly due to economies of scale. However, it's crucial to balance cost with function and brand perception. While cheap options work for some products, they might not offer enough protection or convey the right quality image for others. For items like high-end electronics or beautiful jewelry4, investing a bit more in premium rigid packaging, which can be made efficiently using modern machinery54, often provides much better value by enhancing the customer experience and brand reputation.

| Feature | Cheap Option | Premium (Rigid Box) Option |

|---|---|---|

| Material | Thin cardstock/Kraft | Thick greyboard, art paper12 |

| Structure | Simple folding | Multi-part, glued54 |

| Print/Finish | Minimal/None | Full color, finishes2 |

| Perceived Value | Lower | Higher |

| Ideal For | Budget items, shipping | Luxury goods, gifts4 |

Conclusion

Creating awesome custom packaging involves thoughtful design, fitting materials, and the right making process. Get these right, and your packaging will surely boost your brand appeal.

Disclaimer: I'm Jacob from Kylin Machines (www.kylinmachines.com). We specialize in machinery for producing high-quality rigid boxes and book covers here in China.

-

Discussion on Sourcing Materials (boards, glue, magnets, paper), Document: Rigid Carton Project Supplier from Kyln machine 29 April 2022.docx ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Detailed Watch Box Packaging Plan (materials, processes, finishes) ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Mention of Box Press and Fold Machine for Multiple Shapes, Document: office quote and answer to Jorge.docx ↩

-

Kylin Machine Auto rigid box machine Ky-420B Details, Document: detail of Auto rigid box machine Ky-420B.pdf ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Kylin Machine Box Forming Machine Specifications, Document: quotation1.pdf ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Kylin Machine KY-40 Box Corner Pasting Machine and KY-180 Paper Box Press Machine Details, Document: Distributor Price list To arnold.xlsx ↩ ↩ ↩ ↩ ↩ ↩ ↩

发表回复