What are corrugated boxes?

Are you confused about different box types? Using the wrong packaging can damage products or increase costs. Let's clear up what corrugated boxes really are and why they matter.

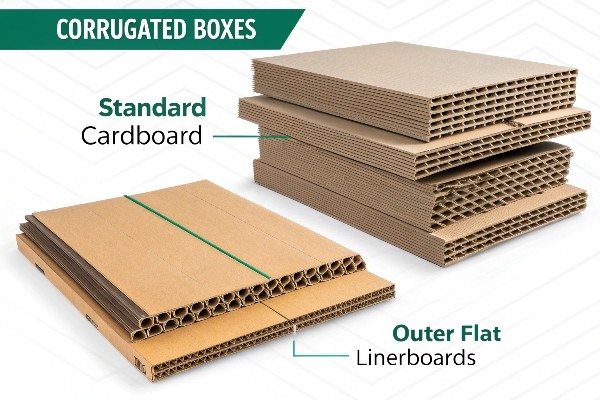

Corrugated boxes are not just 'cardboard'. They are engineered packaging made from layers of paper: two flat linerboards sandwiching a wavy, fluted layer. This structure gives them significant strength for shipping and protection.

Understanding this basic structure is key. But the world of packaging involves many choices, and knowing the differences helps you make the best decision for your products. Let's explore these differences further and see where various box types fit in, especially when considering the entire packaging journey your product takes.

What is the difference between a corrugated and cardboard box?

Do you use the terms "corrugated" and "cardboard" interchangeably? This common confusion can lead to selecting the wrong material for your needs. Let's clarify the real difference right now.

The key difference lies in construction. Corrugated boxes have that specific three-layer structure (liner-flute-liner) for strength. "Cardboard" is often used loosely for thick paperboard or chipboard, typically single-layer, like cereal boxes.

Digging Deeper into the Structure

Let's break this down more. When we talk about corrugated board, the magic is in the layers.

- Linerboard: This is the flat paper that makes up the inner and outer surfaces. It can vary in weight and finish, affecting printability and durability. Kraft paper is common for its strength.

- Fluting (or Medium): This is the wavy layer glued between the liners. The shape and size of these flutes impact the box's characteristics:

- Flute Types: Common types include A (largest, best cushioning), C (good all-around), B (good crush resistance, flatter surface), E (thin, good for printing), and F (very thin). Combinations like BC flute (double wall) offer extra strength.

The combination of these layers creates a lightweight but remarkably strong material, excellent for stacking and resisting impacts during transit.

"Cardboard," on the other hand, usually refers to:

- Paperboard: A single, thicker layer of paper pulp. Think of a shoebox or a cereal box. It's good for folding and printing but lacks the structural rigidity of corrugated.

- Chipboard: Often made from recycled paper, it's dense but less strong than corrugated, used for backing pads or basic boxes.

At Kylin Machine, we work primarily with materials used in rigid boxes, which often involves thicker chipboard or paperboard wrapped with high-quality paper. While we don't make the corrugated material, understanding its properties is crucial because our clients often need both: a premium rigid box (made using technology like our Robotic Spotters) for product presentation, which then might be placed inside a corrugated shipper for safe transport. Knowing the difference ensures the entire packaging system works.

What are corrugated boxes used for?

Wondering where corrugated boxes fit in the packaging landscape? Choosing the wrong box means risking product damage or missing branding opportunities. Let's look at the primary jobs corrugated boxes handle.

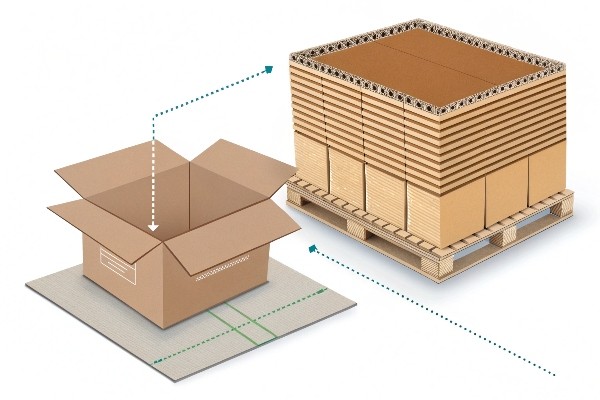

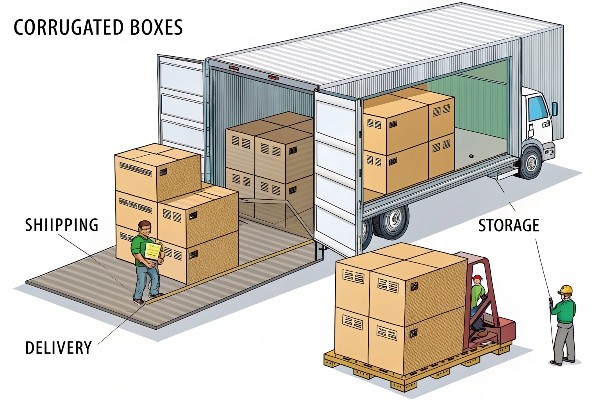

Corrugated boxes are the workhorses for shipping, storage, and protecting goods. Their strength-to-weight ratio makes them ideal for moving products safely through the supply chain, from warehouses to customers' doorsteps.

Applications Across Industries

Corrugated boxes are incredibly versatile due to their protective qualities and relatively low cost. Here are some key areas where you'll find them:

Shipping and Logistics

This is the most common use. Whether it's a manufacturer sending bulk products to a retailer, or an e-commerce business shipping individual orders, corrugated boxes provide the necessary protection against bumps, drops, and stacking pressure during transit. The ability to choose different flute types and board strengths allows customization based on the product's weight and fragility.

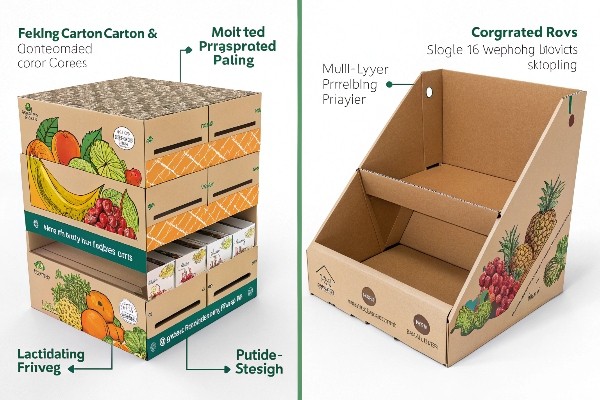

Retail and Point-of-Purchase Displays

While not always their primary function, specially designed and printed corrugated board can be used for floor-standing displays or countertop units in stores. These need to be strong enough to hold products but also offer a surface for branding and marketing messages. Die-cutting allows for creative shapes.

E-commerce Packaging

The boom in online shopping has made corrugated boxes indispensable. They are the standard for shipping everything from books to electronics to clothing. Custom printing on these boxes is also increasingly used for branding purposes, creating an unboxing experience.

Storage

In warehouses and stock rooms, corrugated boxes are used extensively for organizing and storing inventory. Their stackability is a key advantage here.

While corrugated excels at protection and transport, it's often paired with other packaging types. For example, a luxury item might sit in a high-quality rigid box – the kind produced efficiently using Kylin Machine's automated systems like our Hybrid machines for complex shapes – which is then placed inside a sturdy corrugated shipper for its journey. Understanding the role of each type helps create the optimal packaging solution from start to finish.

| Feature | Corrugated Box Usage Examples | Key Benefit |

|---|---|---|

| Shipping | E-commerce orders, bulk goods, moving boxes | Protection, Stackability |

| Retail POP | Floor displays, countertop units (thicker grades) | Strength, Printability |

| Storage | Warehouse inventory, archive boxes | Durability, Cost |

| Primary Pack | Sometimes for larger items (e.g., pizza boxes) | Containment, Cost |

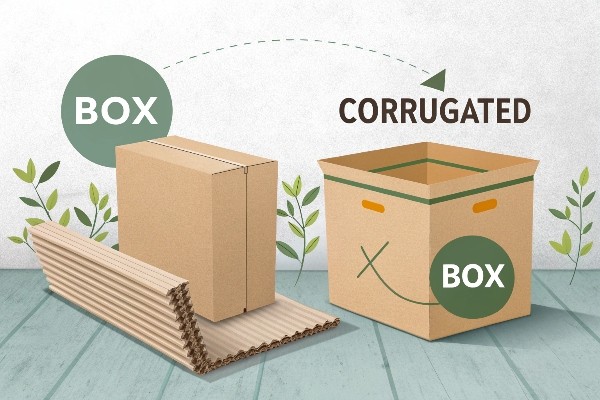

What is the difference between box and corrugated?

Is every 'box' a 'corrugated box'? Using these terms loosely can blur the lines between very different packaging solutions. Let's clarify the relationship between the general term and the specific type.

"Box" is a broad term for any container, often rectangular. "Corrugated" refers to a specific construction method involving fluted paper between liners. So, a corrugated box is one type of box, but not all boxes are corrugated.

Understanding the Box Universe

Think of "box" as the parent category. Underneath it sit various species, each suited for different habitats.

- Corrugated Boxes: Defined by their liner-flute-liner structure. Their main job is protection, stacking strength, and shipping. They are the tanks of the box world.

- Folding Cartons: Made from a single layer of paperboard, designed to be shipped flat and folded into shape. Think cereal boxes, cosmetic boxes, pharmaceutical packaging. They prioritize printability and shelf appeal over heavy-duty protection.

- Rigid Boxes (or Set-up Boxes): These are sturdy boxes made from thick chipboard, typically wrapped with paper or other materials. They don't fold flat and convey a sense of luxury and permanence. Think high-end electronics (like smartphones), board games, or gift boxes.

This last category, rigid boxes, is where Kylin Machine focuses its expertise. Our machines, like the Robotic Spotter for precise placement and Hybrid machines for complex structures, are designed to automate the production of these premium boxes.

Here’s a simple comparison:

| Feature | Corrugated Box | Folding Carton | Rigid Box |

|---|---|---|---|

| Material | Linerboard & Fluting | Paperboard (single layer) | Chipboard + Wrap |

| Construction | Multi-layer, strong structure | Folds flat, lighter weight | Sturdy, does not collapse |

| Primary Use | Shipping, Protection, Storage | Retail shelf packaging | Luxury goods, presentation |

| Strength | High | Moderate | Very High (for its purpose) |

| Kylin Focus? | No (indirectly via shipping) | No | Yes (Our core machinery) |

So, while a customer might just ask for a "box," understanding the specific type they need – corrugated for shipping, folding carton for the shelf, or a rigid box for premium presentation – is critical. We help our clients excel in producing those high-value rigid boxes efficiently.

What is the difference between folding carton and corrugated?

Choosing between a folding carton and a corrugated box? Making the wrong call impacts everything from product safety to shelf appeal and cost. Let's pinpoint the key differences clearly.

Corrugated is multi-layered with fluting for strength, ideal for shipping. Folding cartons are single-layer paperboard, easily printed and folded, perfect for retail shelves but offering less protection during transit.

Key Distinctions for Packaging Choices

These two box types serve very different purposes, driven by their construction and material properties.

-

Material & Structure:

- Corrugated: As we've discussed, it's the liner-flute-liner sandwich. This creates air pockets (cushioning) and structural beams (strength).

- Folding Carton: Made from paperboard, which is essentially thick paper stock. It's a single layer, much denser but without the engineered structure of corrugated.

-

Strength & Protection:

- Corrugated: Designed for protection against impacts, crushing, and stacking forces. The clear winner for shipping.

- Folding Carton: Offers minimal protection, mainly containing the product and providing a printable surface. Not suitable for rough handling on its own.

-

Printability & Finish:

- Corrugated: Can be printed, but achieving high-resolution graphics directly on the outer liner (especially on Kraft) can be challenging or require special techniques (like litho-lamination).

- Folding Carton: Paperboard offers a smooth, uniform surface ideal for high-quality offset or digital printing, varnishes, embossing, and foil stamping. Perfect for grabbing attention on a retail shelf.

-

Form & Assembly:

- Corrugated: Often comes partially assembled (glued or stitched) or requires strong tape for closure. Can be bulky.

- Folding Carton: Ships flat to save space and cost, easily folded and tucked or glued into shape at the point of packing.

-

Cost:

- Corrugated: Generally more expensive per unit due to more material and complex manufacturing, but offers superior protection, potentially saving costs from damaged goods.

- Folding Carton: Typically less expensive per unit, especially in high volumes.

In my experience at Kylin Machine, businesses often use both. A product might be packaged in a beautifully printed folding carton for the shelf, and then multiple cartons might be packed into a master corrugated box for shipping to retailers. Or, for a higher-end feel, they might skip the folding carton and use a rigid box (made with our tech) instead, which then goes into a corrugated shipper. Knowing these differences helps our clients choose the right primary and secondary packaging.

| Feature | Folding Carton | Corrugated Box |

|---|---|---|

| Material | Paperboard (single layer) | Linerboard & Fluting (multi-layer) |

| Strength | Low to Moderate | High |

| Protection | Minimal | Excellent |

| Print Surface | Excellent (smooth) | Good (can be uneven) |

| Primary Use | Retail Packaging, Shelf Appeal | Shipping, Protection, Storage |

| Assembly | Ships flat, folds easily | Often pre-glued or needs tape |

| Cost | Generally Lower | Generally Higher |

Conclusion

Corrugated boxes are strong, layered containers vital for shipping. They differ significantly from single-layer 'cardboard' or folding cartons. Understanding these types helps select the best packaging for protection and presentation.

About Me:

In warehouses and stock rooms, corrugated boxes are used extensively for organizing and storing inventory. Their stackability is a key advantage here.

While corrugated excels at protection and transport, it's often paired with other packaging types. For example, a luxury item might sit in a high-quality rigid box – the kind produced efficiently using Kylin Machine's automated systems like our Hybrid machines for complex shapes – which is then placed inside a sturdy corrugated shipper for its journey. Understanding the role of each type helps create the optimal packaging solution from start to finish.

Website: www.kylinmachines.com

Brand: Kylin Machine

发表回复