What are the types of carton boxes?

Struggling to choose the right box? Confused by all the different names and types? Let's clear things up so you can pick the best packaging for your products.

Carton boxes generally fall into three main categories: folding cartons (like cereal boxes), rigid boxes (like high-end gift boxes), and corrugated boxes (used for shipping). Understanding these types helps you select the right packaging solution based on protection, presentation, and cost.

Knowing the differences between these box types is really important. It affects how your product looks, how well it's protected, and your overall costs. As someone who works with packaging machinery every day at Kylin Machine, I see how crucial the right box choice is. Let's dive into the main categories to help you make a smart decision for your business.

How many types of carton box are there?

Feeling overwhelmed by the sheer number of box options out there? Unsure where to even begin your search? Let's break down the main categories to make your packaging decisions much simpler.

While you can find countless specific box styles, most carton boxes fit into three broad categories: folding cartons, rigid boxes, and corrugated boxes. Each type offers unique characteristics and advantages for different packaging needs.

!

It might seem like there's an endless variety of boxes, and in a way, there is. You have boxes for specific products, boxes with special openings, boxes with windows, and so on. But from a structural and manufacturing standpoint, they usually start from one of the three core types. Thinking in terms of these main categories helps a lot.

Why Categorize Boxes?

Categorizing helps you narrow down your choices based on what you really need.

- Function: Are you focused on basic retail display, creating a luxury experience, or ensuring maximum protection during shipping?

- Cost: Different constructions and materials have vastly different costs.

- Production: The machinery needed to make each type varies. At Kylin Machine, for instance, we specialize in equipment for high-quality rigid boxes.

Key Factors in Choosing

When you're deciding, think about:

- Product Weight & Fragility: Heavier or more delicate items need stronger boxes.

- Presentation: Does the box need to look premium (like for jewelry or electronics)? Rigid boxes excel here.

- Shipping Journey: Will it travel far or endure rough handling? Corrugated is often the answer.

- Budget: Folding cartons are usually the most budget-friendly, while rigid boxes command a higher price but offer perceived value.

Understanding these main types is the first step to choosing effectively.What are the three types of boxes?

Need the specifics on the main box types? Confused about the difference between folding, rigid, or corrugated? Let's look at the core features of each to help you match the right box to your products.

The three primary types are folding cartons (made from thinner paperboard, shipped flat), rigid boxes (sturdy, pre-formed, often used for luxury items), and corrugated boxes (layered with fluting for strength, ideal for shipping).

Let's break down each of these main categories. I work with clients making all sorts of packaging, but my focus at Kylin Machine is often on the machinery for rigid boxes, so I know that category particularly well.Folding Cartons

These are probably the most common boxes you see on retail shelves.

- Material: Made from paperboard, which is essentially a thick paper stock. It can be coated or uncoated.

- Construction: They are produced as flat blanks, then folded and often glued by the packer or a machine. Think cereal boxes or toothpaste boxes.

- Pros: Cost-effective, lightweight, prints well, stores efficiently when flat.

- Cons: Offers limited protection compared to other types, doesn't feel as premium.

Rigid Boxes (or Set-Up Boxes)

These are the boxes that signal quality and luxury.

- Material: Constructed from thick, dense chipboard (often called greyboard), which is then wrapped with paper, leatherette, or fabric.

- Construction: They arrive pre-formed and don't collapse flat. Think iPhone boxes, high-end board game boxes, or elegant jewelry boxes. This is the category Kylin Machine specializes in providing machinery for.

- Pros: Very strong and durable, excellent presentation, high perceived value, great protection.

- Cons: More expensive to produce, bulkier to ship and store before filling.

Corrugated Boxes

These are the workhorses of the packaging world, especially for shipping.

- Material: Made from corrugated fiberboard – this involves one or more layers of fluted paper sandwiched between flat linerboards.

- Construction: The fluting creates air pockets that provide cushioning and strength. Think standard shipping boxes or pizza boxes.

- Pros: Excellent strength-to-weight ratio, great protection and cushioning, stackable, recyclable.

- Cons: Not typically used for primary luxury presentation (though printing techniques are improving), can be bulky.

Here's a quick comparison:

| Feature | Folding Carton | Rigid Box | Corrugated Box |

|---|---|---|---|

| Material | Paperboard | Chipboard + Wrap | Corrugated Fiberboard |

| Construction | Shipped flat, needs folding | Pre-formed, non-collapsible | Layered with fluting |

| Strength | Low | High | Very High (for shipping) |

| Appearance | Good for retail | Premium, Luxury | Utilitarian (often) |

| Primary Use | Retail packaging | Luxury goods, Gift boxes | Shipping, Bulk packaging |

| Cost | Low | High | Medium |

What are the three types of cardboard?

Is the term "cardboard" causing confusion? Unsure about the difference between paperboard, corrugated, and chipboard? Let's clarify the materials themselves to help you make better box choices.

Generally, "cardboard" refers loosely to three main paper-based materials: paperboard (a thick paper stock for folding cartons), corrugated fiberboard (layered sheets with fluting for shipping boxes), and chipboard/greyboard (dense board made from recycled paper, used for rigid boxes).

People often use "cardboard" as a catch-all term, but in the packaging industry, we differentiate between the materials because their properties and uses are quite distinct. Getting the material right is just as important as getting the box style right.

Paperboard

Think of this as a heavier, stiffer version of paper.

- What it is: Made by pressing fibrous pulp (often from wood or recycled paper) into sheets. It comes in various thicknesses (calipers) and can have different coatings to improve printability or create barriers (like for food).

- Common Types: SBS (Solid Bleached Sulfate) is common for high-quality printing. CUK (Coated Unbleached Kraft) is strong and often used for beverage carriers.

- Main Use: The primary material for folding cartons.

Corrugated Fiberboard

This is what most people mean when they talk about a "cardboard box" for shipping.

- What it is: It’s a multi-layered material. It has flat outer sheets called linerboards and a wavy, fluted layer in between. This structure provides significant strength and cushioning.

- Variations: Comes in different thicknesses (single wall, double wall, triple wall) and flute sizes (like A, B, C, E, F flutes), which affect strength and printability.

- Main Use: Shipping boxes, mailers, and some retail displays that need extra strength.

Chipboard / Greyboard

This is a dense, strong board often made from reclaimed paper fibers.

- What it is: Recycled paper fibers are compressed tightly into a rigid sheet. It's usually not coated or meant for high-end printing on its own surface (it gets wrapped). Greyboard is a common type we see used as the core for the rigid boxes our Kylin machines help produce.

- Properties: Very stiff and resistant to bending. Provides excellent structural integrity.

- Main Use: The structural core of rigid boxes, backing for notepads, book covers, puzzle pieces.

Understanding these material differences helps explain why the different box types perform the way they do.What are the names of different types of cardboard?

Need to get more specific about cardboard names? Feeling lost with terms like SBS, Kraft, C-Flute, or Greyboard? Let's look at some common names used to classify these materials more precisely.

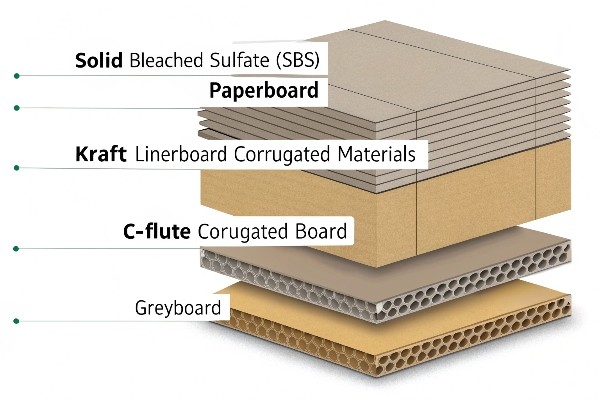

Specific cardboard names often describe the material's composition, structure, or intended use. Examples include Solid Bleached Sulfate (SBS) paperboard, Kraft linerboard for corrugated, C-flute corrugated board, and dense Greyboard used inside rigid boxes.

Knowing the specific names helps when you're sourcing materials or discussing requirements with suppliers or manufacturers like us at Kylin Machine. It ensures everyone is talking about the same thing. Let's revisit the main categories with some more specific names.Paperboard Names

These often relate to the pulp used and any coatings applied.

- SBS (Solid Bleached Sulfate): Made from bleached chemical pulp. Known for its brightness and smooth surface, great for high-quality graphics on folding cartons (cosmetics, pharmaceuticals).

- CUK (Coated Unbleached Kraft): Strong, tear-resistant paperboard made from unbleached kraft pulp, often coated on one side. Good for beverage carriers, hardware packaging.

- CRB/CCNB (Coated Recycled Board / Clay Coated News Back): Made primarily from recycled fibers, often with a white top coat for printing and a grey or brown back. A cost-effective option for things like cereal boxes or shoe boxes.

Corrugated Fiberboard Names

These usually specify the structure (wall type, flute size) and sometimes the liner material.

- Flute Types: Identified by letters (A, B, C, E, F are common). 'C-Flute' is a very common all-purpose flute for shipping boxes. 'E-Flute' and 'F-Flute' are much thinner ('microflutes'), sometimes used for primary packaging with good printability.

- Wall Types: 'Single Wall' (one fluted layer), 'Double Wall' (two fluted layers, e.g., 'BC-Flute'), 'Triple Wall' (three fluted layers) for heavy-duty applications.

- Liner Names: 'Kraft' liner is made from virgin wood fibers and is stronger. 'Test' liner typically includes recycled content.

Chipboard / Greyboard Names

These are often less standardized and might be referred to by thickness (caliper) or density.

- Greyboard: This is a very common term for the dense, rigid board made from recycled paper, typically grey in color, used as the structural core for rigid boxes. This is the key material our customers use with Kylin Machine's rigid box making equipment.

- Plain Chipboard: A general term for basic, uncoated chipboard.

- Bending Chipboard: A type designed to be scored and folded without breaking easily.

Here’s a simple table:

| Category | Common Specific Names/Types | Typical Use |

|---|---|---|

| Paperboard | SBS, CUK, CCNB | Folding Cartons (retail) |

| Corrugated | C-Flute, B-Flute, E-Flute, Kraft Liner, Test Liner, Single/Double Wall | Shipping Boxes, Mailers |

| Chipboard | Greyboard, Plain Chipboard | Rigid Box Cores, Book Covers, Backing |

Knowing these names helps you specify exactly what you need for your packaging project.

Conclusion

Choosing the right carton involves understanding box types like folding, rigid, and corrugated, plus the materials like paperboard, chipboard, and corrugated fiberboard. Kylin Machine focuses on machinery for premium rigid boxes.

发表回复