What printing techniques are available for rigid boxes?

Struggling to choose the right print for your rigid boxes? Poor printing can hurt your brand. Learn the best techniques to make your packaging truly stand out and impress customers.

Rigid boxes typically use offset lithography (litho), digital printing, screen printing, or flexography. Often, a printed sheet (wrap) is laminated onto the rigid greyboard structure, allowing for high-quality graphics and finishes.

Choosing the right printing method is crucial for your rigid box project. It affects the look, feel, cost, and even the production speed. Let's explore the options available so you can make an informed decision that benefits your packaging goals. Read on to discover more.

What is rigid printing?

Need clarity on "rigid printing"? Confusing terms lead to costly mistakes. Understand exactly what it means to ensure your packaging has the premium look and feel it deserves.

Rigid printing usually refers to printing techniques suitable for rigid substrates or, more commonly in packaging, printing high-quality graphics onto paper wraps that are then laminated onto the structural greyboard of a rigid box.

Diving Deeper into Rigid Printing

When we talk about "rigid printing" in the context of luxury boxes, it's less about printing directly onto the thick greyboard itself (which is possible but less common for high graphics) and more about the process of creating the decorated exterior.

Think of it in these steps:

- Printing the Wrap: High-quality printing happens on a thinner paper or cardstock sheet. This is where techniques like offset lithography shine, offering sharp details and vibrant colors. Digital printing is also a great option, especially for shorter runs or variable data.

- Applying Finishes: Before wrapping, this printed sheet can get special treatments like lamination (matte or gloss), UV coating, foil stamping, or embossing/debossing to add texture and visual appeal.

- Laminating/Wrapping: The printed and finished sheet is then precisely glued and wrapped around the assembled rigid greyboard structure. This is a critical step where precision matters greatly.

This wrap-based approach allows for the best of both worlds: the sturdiness of a rigid box and the detailed, colorful graphics achievable with advanced printing on paper. In my experience at Kylin Machine, achieving that perfect wrap alignment consistently requires sophisticated machinery, especially for complex box designs. Our robotic spotter systems, for example, are designed specifically to handle this precise placement task, ensuring a flawless finish every time.

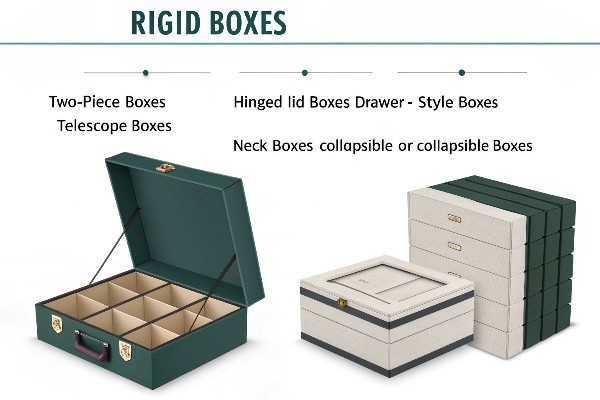

What are the different types of rigid boxes?

Wondering which rigid box style fits your product? Choosing incorrectly can compromise protection and presentation. Discover the common types to find the perfect match for your needs.

Common rigid box types include two-piece boxes (lid and base, telescope boxes), hinged lid boxes, drawer-style boxes (slipcases), neck boxes (with an inner tray), and collapsible or foldable rigid boxes.

Exploring Rigid Box Styles and Their Printing Needs

The style of rigid box you choose impacts not just the unboxing experience but also the practicalities of printing and assembly. Each type has unique surface areas and construction methods.

Here's a breakdown of common types:

| Box Type | Description | Printing/Finishing Considerations |

|---|---|---|

| Two-Piece | Separate base and lid (full or partial telescope). Classic and versatile. | Large flat surfaces on lid/base are ideal for bold graphics/branding. |

| Hinged Lid | Lid is attached to the base, often with a magnetic closure or ribbon tie. | Continuous designs across the hinge need careful alignment. |

| Drawer (Slipcase) | A sleeve covers an inner tray that slides out like a drawer. | Printing possible on both sleeve and inner tray; unboxing reveal. |

| Neck Box | Features an inner "neck" tray, creating a distinct separation/reveal. | Offers multiple surfaces (lid, base, neck) for printing details. |

| Collapsible | Ships flat and is easily assembled; saves on shipping/storage space. | Requires precise scoring/folding; printing must align after assembly. |

The complexity increases with features like windows, magnetic closures, or custom inserts. Printing needs to complement the structure. For instance, a hinged lid box might have branding on the top, inside lid, and base. Collapsible boxes, while economical for shipping, demand high precision in both printing registration and the die-cutting/gluing process to ensure they assemble correctly and look premium. We work closely with clients at Kylin Machine to ensure our equipment, like our specialized machines for collapsible boxes, can handle these precise manufacturing requirements effectively.

What printing method is used on cardboard?

Confused about printing directly on cardboard? Using the wrong method results in poor quality or high costs. Learn the suitable techniques for printing effectively on various cardboard types.

Common printing methods for cardboard include offset lithography (often via lamination for high quality), flexography (especially for corrugated), digital printing (good for short runs/customization), and screen printing (for simple, bold graphics).

Comparing Cardboard Printing Methods

Printing on cardboard presents different challenges compared to printing on paper wraps for rigid boxes. Cardboard surfaces can be rougher (like corrugated) or smoother (like folding cartons). The best method depends on the desired quality, volume, and budget.

Let's look at the main options:

- Offset Lithography:

- How it works: Ink transferred from plate to blanket to cardboard.

- Best for: High-quality graphics on smoother cardboard or via litho-lamination (printing on paper then gluing to cardboard).

- Pros: Excellent image quality, cost-effective for large volumes.

- Cons: High setup cost, not ideal for very rough surfaces directly.

- Flexography:

- How it works: Ink transferred via flexible relief plate.

- Best for: Corrugated cardboard, shipping boxes, simpler graphics, large volumes.

- Pros: Fast, durable prints, works on rough surfaces, lower plate cost than offset.

- Cons: Lower image resolution than offset, color consistency can be challenging.

- Digital Printing:

- How it works: Inkjet or toner applied directly based on digital file.

- Best for: Short runs, prototypes, personalized/variable data printing.

- Pros: No plates needed, quick setup, excellent for customization.

- Cons: Slower speed for large volumes, potentially higher cost per unit on long runs.

- Screen Printing:

- How it works: Ink pushed through a mesh screen onto the cardboard.

- Best for: Bold, simple designs, spot colors, printing on thick or unusual shapes.

- Pros: Durable ink layer, vibrant colors, versatile for different surfaces.

- Cons: Slow process, limited detail/halftones, not cost-effective for multi-color complex jobs.

For the high-end look typically associated with rigid boxes (even though they use greyboard, not standard 'cardboard'), litho-lamination remains a top choice, combining offset's quality with the board's strength.

What type of printing is used for packaging?

Overwhelmed by printing choices for packaging? Making the wrong decision impacts brand perception and budget. Get a clear overview of the main printing types used across packaging applications.

Packaging printing utilizes various methods like offset lithography, flexography, digital printing, rotogravure, and screen printing, chosen based on the substrate (paper, plastic, metal), desired quality, run size, and budget.

Overview of Major Packaging Printing Techniques

Packaging is diverse, ranging from flexible pouches and labels to folding cartons and rigid boxes. The printing technique must match the material, product requirements, and market positioning.

Here’s a broader look:

- Offset Lithography: King for high-quality graphics on paper and paperboard (folding cartons, rigid box wraps). Offers sharp details and consistent color, ideal for premium brands. As discussed, often used in litho-lamination for corrugated and rigid boxes.

- Flexography: Dominant in flexible packaging (bags, pouches), labels, and corrugated boxes. It's fast and cost-effective for large runs, handling various substrates well. Quality has improved significantly over the years.

- Digital Printing: Rapidly growing, especially for short runs, personalization, and prototypes across labels, cartons, flexibles, and even corrugated. Offers quick turnarounds and no plate costs. Great for market testing or seasonal items.

- Rotogravure: Known for extremely high quality and consistency over very long runs. Excellent for fine details and photographic images. Often used for high-volume flexible packaging, decorative laminates. High cylinder setup costs make it unsuitable for short runs.

- Screen Printing: Used for bold graphics, special effects (like high-build varnishes), and printing directly onto shaped containers (bottles, tubes). Offers excellent ink opacity.

In my field focusing on rigid boxes and book covers at Kylin Machine, the critical link is often the finishing and assembly after printing. Regardless of the printing method chosen for the wrap (usually offset or digital for quality), the precision of applying that wrap using automated systems like our Robotic Spotters or Hybrid machines is what ensures the final product meets luxury standards. Efficiency and accuracy in post-press are just as vital as the print quality itself.

Conclusion

Choose offset, digital, flexo, or screen printing for rigid boxes, often applied via laminated wraps. Select based on quality needs, volume, and budget for impactful packaging.

About me:

My name is Jacob, and I work with Kylin Machine (www.kylinmachines.com). We are based in China and specialize in advanced post-press machinery, particularly Robotic Spotter and Hybrid systems for rigid box and hardcover production. We help businesses in the Graphic Arts, Paper Converting, and Bookbindery industries worldwide achieve high-quality, efficient production. We operate on a B2B, wholesale-only model.

发表回复